3DESIGN

3.1 Wire Ropes

A wire rope is made up of a number of fibre or

steel wire strands laid helically around a core. The

strands themselves are composed of a number of

wires laid in various geometrical configurations.

Ropes are manufactured from steel wires which

are drawn from steel rods melted in open– hearth

or electric furnaces. The wire rope construction,

types and other terms used in this guideline are

described in the glossary.

3.1.1 Rope geometry

One of the basic challenges in the design and

construction of ropeway is to determine the shape

of curve of the loaded rope and to calculate the

precise forces acting upon it.

The shape of the rope curve is influenced by the

weight of the rope, the weight of the trolley that

slides upon it, the load in the trolley, wind load,

the friction developed on the supports (towers)

and the braking friction at rope or at the stations

during stoppage and icing (in cold places). In

each case, the curve has to be determined for

maximum and minimum conditions i.e. for rope

only and the line fully loaded. In these conditions,

the maximum sag of the rope and the bending

angles due to load on the supporting towers

at the two ends must be evaluated. Each rope

is exposed to tension caused by initial stresses

due to tension weight, the rope's own weight and

the weight of the loaded trolley at its maximum

carrying capacity (120 kg in the case of gravity

ropeway). The shape of the curve varies according

to the way the rope is fixed, its alignment, angle

of inclination and the number of spans (if the

gravity ropeway has more than one span).

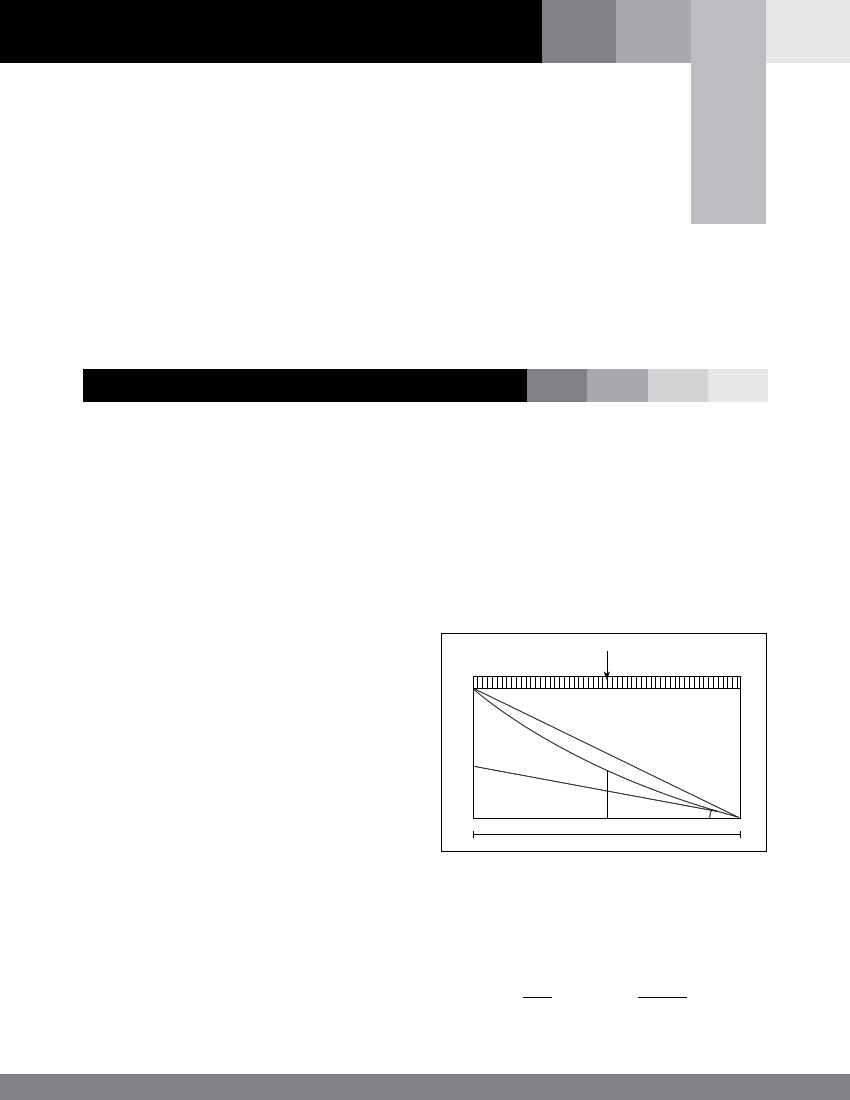

A) Uniformly distributed load along the rope span in

plan

w

4b

h

h-4b

y|

y1

I

x

β

Figure 14: Uniformly distributed load along the rope span in plan

In the above diagram,

y = y1+ y|

Where y1 = 4bx2 and y| = (h-4b)x

l2 l

17